Equipment for meat processing, dairy, fish, and canning enterprises, including components, replacement units, and spare parts for seaming machines, fillers, conveyors, washers, and other machinery for processing food raw materials.

EQUIPMENT SPARE PARTSA 20-Year History of Success

SP Teslenko O.S. manufactures and supplies state-of-the-art food industry equipment that operates successfully in numerous meat processing plants, fish factories, dairy complexes, and canning facilities across Ukraine and beyond.

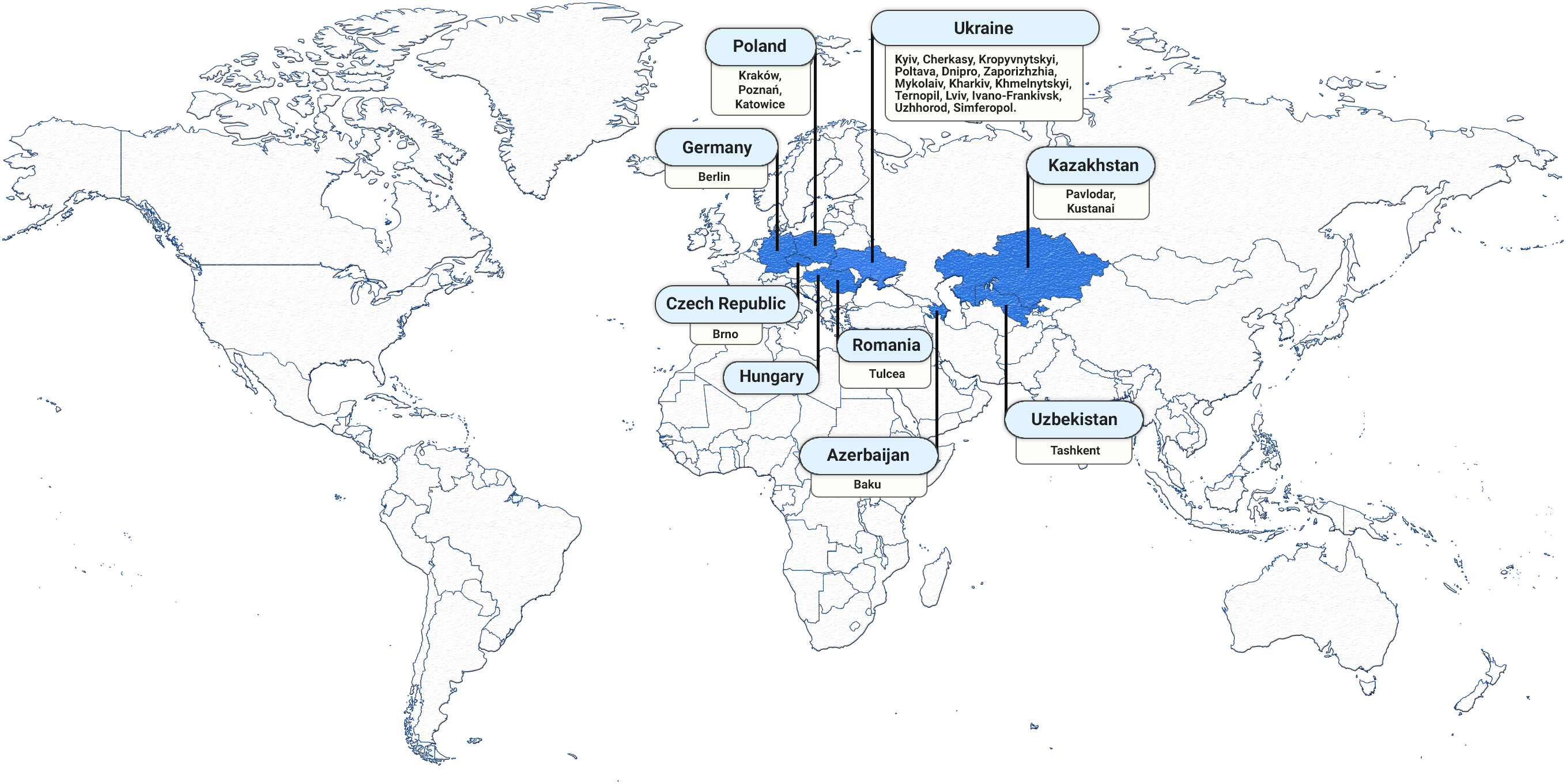

With over 20 years of experience, SP Teslenko O.S. has played a key role in supporting the food industry in Ukraine, as well as in European and Asian countries.

Today, our equipment is reliably in operation in Ukraine, Poland, Germany, the Czech Republic, Romania, Azerbaijan, Kazakhstan, Uzbekistan, and many other countries.

We offer you:

Additionally, we provide production line assembly, installation, and both warranty and ongoing maintenance for the equipment delivered to our clients.

In addition, based on customer preferences, the machines can be equipped with frequency converters (inverters) from "Omron" (Japan) or "Schneider Electric" (Austria), enabling smooth adjustment of equipment performance within specified ranges.

SP Teslenko O.S. provides: manufacturing supply modernization repair of the following equipment:

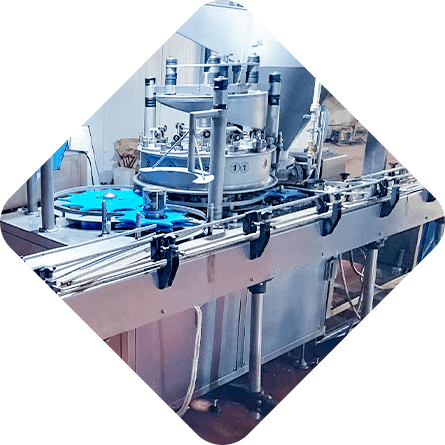

Production lines for canned goods, including machines for container preparation, filling, seaming, transporting, washing, and sterilizing cans.

KZK-109 seaming machines for sealing glass jars of the SСO type with capacities ranging from 0.25 to 1.0 liters, with a guaranteed output of up to 120 jars per minute.

KZK-110 seaming machines for sealing glass jars of the SСO type with a capacity of 3.0 liters, with a guaranteed output of up to 63 jars per minute.

KZK-79 seaming machines for sealing tin cans with capacities up to 1.0 liter, with a guaranteed output of up to 120 cans per minute.

KZK-79A seaming machines for sealing tin cans with capacities up to 1.0 liter, with a guaranteed output of up to 120 cans per minute.

KZK-79A01 seaming machines for sealing tin cans with capacities up to 1.0 liter, equipped with a mechanical reducer and a guaranteed output of up to 120 cans per minute.

KZK-14 seaming machines for sealing metal tin cans with a diameter of 153.1 mm and capacities up to 5 liters.

KZK-141 seaming machines for sealing tin cans with capacities from 0.2 to 1.5 liters, with an output of up to 180 cans per minute. The machine can also be equipped with an interchangeable unit for sealing tin cans with a diameter of 153 mm, providing an output of up to 70 cans per minute when the unit is installed.

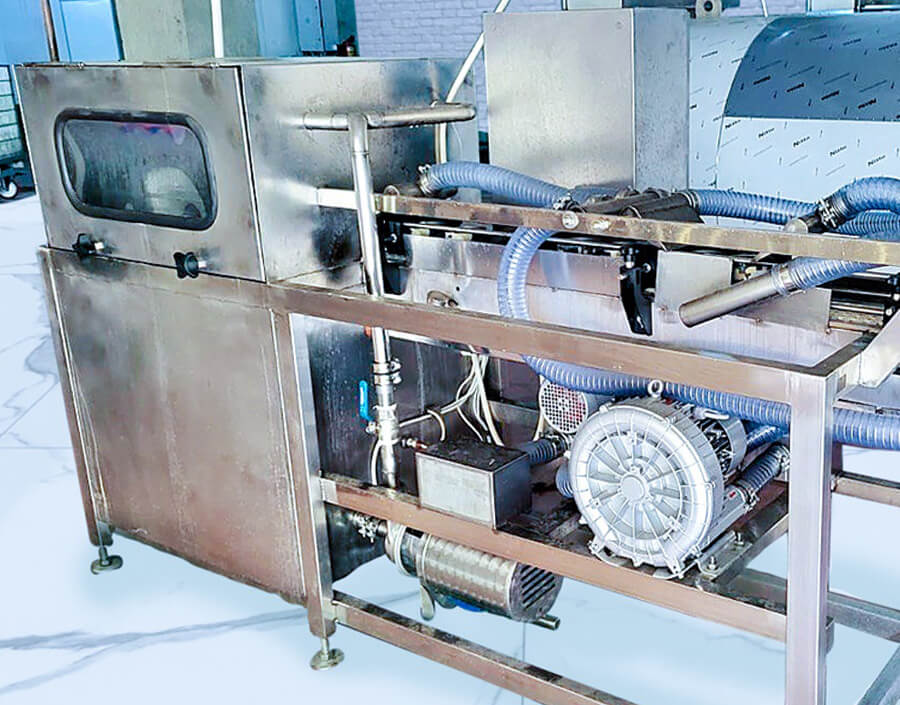

MBU-1 universal can-washing machines for washing and rinsing sealed cans before sterilization.

MBU-2 universal can-washing machines for washing and drying sealed cans after sterilization.

OBP-1 universal can-washing machines for rinsing empty tin cans with water and subsequent scalding.

TLB-1 universal belt conveyors for transporting empty and filled cans.

V2-FNA type automatic filling machines for filling cans with meat.

Attention

At the customer’s request, we adapt our equipment to produce products in tin cans with diameters ranging from 50 mm to 99 mm and heights from 25 mm to 240 mm on KZK-79 machines, and with a diameter of 153.1 mm and heights up to 320 mm on KZK-14 machines.

If needed, seaming machines can be equipped with a steam injection system under the lid, significantly enhancing the quality of canned meat products.

Our specialists can visit the client’s facility to perform the modernization of seaming machines directly at their production site. This includes reconfiguring the equipment to handle different types of containers (from glass to tin and vice versa).

Our Clients: Producers of Canned Goods from Various Countries

We supply high-quality food processing equipment to manufacturers worldwide, supporting our clients in growing their businesses and ensuring product quality.

The delivery timeline for equipment is specified in the supply contract and depends on the scope of supply, the complexity of manufacturing, and equipment modifications.

The delivery period begins upon receipt of the prepayment, the amount of which is also specified in the contract. Early delivery of equipment is allowed.

Service Complex from SP Teslenko O.S.

Teslenko O.S. is your partner in the production and supply of equipment for meat processing, dairy, fish, and other canning enterprises. We offer not only modern technologies but also a full range of services to ensure the seamless operation of your business. For our clients, we provide a wide range of professional services covering all stages from equipment selection to maintenance.

Consultations and Equipment Supply

Assistance in selecting the optimal solutions for your production and prompt delivery of original spare parts.

Installation and Commissioning Works

We install and adjust the supplied equipment at the customer's facilities.

Reconstruction of Canning Lines and Workshops

Production modernization to improve efficiency.

Warranty and Service Maintenance

The equipment supplied by our company meets the declared technical requirements. The warranty period is at least 1 year, provided the technical operation rules are followed.

English

English